Hydrogen is emerging as a promising option to decarbonize power generation, transportation, and other industries. One of the most significant barriers to scaling up hydrogen use is the lack of a transportation network. Currently, hydrogen is transported via high-pressure tube trailers and liquefied hydrogen tankers, but these methods are not economically feasible for large-scale and long-distance transportation. Today, around 1,600 miles of hydrogen pipelines are operating in the U.S., and they are mostly concentrated near large chemical plants and petroleum refineries. While transporting gaseous hydrogen via existing pipelines is a cost-effective option for local transportation, the high upfront capital costs associated with constructing new pipelines present a significant barrier for large-scale transportation.

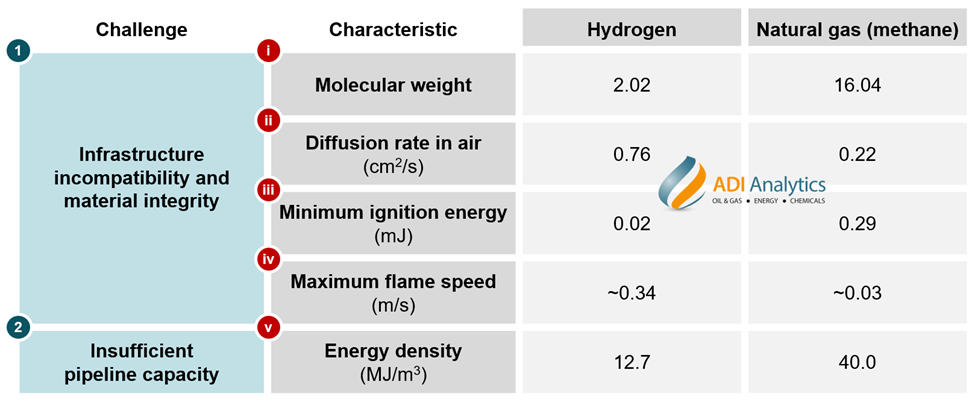

In response, the idea of repurposing existing natural gas infrastructure for hydrogen transportation is being explored. ADI Analytics has been assisting many companies evaluate the feasibility of blending hydrogen with natural gas for transport through existing pipelines, instead of transporting 100% hydrogen. However, this approach comes with its own set of challenges, primarily due to the distinct physical and chemical characteristics of hydrogen compared to methane, the primary component of natural gas, as illustrated in exhibit 1.

Exhibit 1: Comparison of key characteristics of hydrogen and natural gas (methane)

These differences in characteristics create significant challenges when trying to use existing natural gas infrastructure to transport hydrogen. Some of the key challenges include:

- Infrastructure incompatibility and material integrity: Hydrogen has a molecular weight that is one-eighth of methane’s and has a higher diffusion rate than methane. As a result, hydrogen is more likely to leak from seals , gaskets, and piping joints. When hydrogen atoms are absorbed and diffused within pipeline metals such as steel, they can affect the metal’s fatigue- and fracture-resistance properties, potentially shortening the lifespan of pipelines. Even tiny amounts of hydrogen can accelerate material degradation, posing safety risks such as leaks and explosions.

To address these issues, specialized materials, coatings, or liners may be required for pipelines, but these solutions add costs and may not be feasible for repurposing aging pipelines. Additionally, hydrogen’s ignition and flame properties increase the risk of flashback, which may be encountered during the ignition of gas leaked from confined spaces within the transportation system, reducing existing infrastructure compatibility.

- Insufficient pipeline capacity: Natural gas pipelines are designed for methane, which has a much higher energy density than hydrogen. Hydrogen, with only one-third the energy density of methane, requires three times the volume to produce the same amount of energy, placing significant strain on current pipeline capacity when natural gas production is increasing and key routes may have limited capacity. Also, existing compressors and valves would need to be retrofitted or replaced to handle the increased pressure required for hydrogen. Changes in pressure to accommodate hydrogen could increase the risk of pipeline failure.

While hydrogen holds significant potential for reducing carbon emissions and supporting decarbonization efforts, repurposing existing natural gas infrastructure for pure hydrogen transportation is technically difficult, risky, and costly. As the hydrogen market continues to evolve, monitoring infrastructure development and technological advancements will be key to address these challenges.

– Bhautik Gajera

ADI Analytics is a prestigious, boutique consulting firm specializing in oil & gas, energy transition, and chemicals since 2009. We bring deep, first-rate expertise in a broad range of markets including hydrogen, ammonia, and other chemical where we support Fortune 500, mid-sized and early-stage companies, government agencies, and investors with consulting services, research reports, and data and analytics, with the goal of delivering actionable outcomes to help our clients achieve tangible results.

We also host the ADI Forum, one of Houston’s distinguished industry conferences, to bring c-suite executives together for meaningful dialogue and strategic insights across the oil & gas, energy transition, and chemicals value chains. Learn more about the ADI Forum, which is chaired by Uday Turaga, Founder & CEO, ADI Analytics, at www.adi-forum.com.

Subscribe to our newsletter or contact us to learn more.