The mining industry has traditionally been slow to adopt new technologies due to the scale and complexity of its operations, and the heavy costs that come with this change. However, mining is now seeing the growing implementation of new digital technology and related innovations.

There are three themes that are expected to be central to the digitization of the mining industry over the next few years. First, the use of automation, robotics, and digitally-enabled hardware tools to take over activities traditionally carried out by human-controlled machinery is already growing within the mining and metals industry. Important technologies in this area include 3D printing, automated exploration drones, robotic trucks and trains, sensors, and autonomous robots, drills, trucks.

Second, companies are having a digitally enabled workforce by using connected mobility and technology, and virtual and augmented reality to monitor field, remote, and centralized workers in real-time. For instance, equipping workers with connected, intelligent wearables and mobile devices allows mines to capture critical information in real-time. It also creates seamless communication and immediate, remote expert assistance.

Finally, application of algorithms and artificial intelligence (AI) to process data can help with real-time decision support and future projections. For example, gold producer Goldcorp was using advanced analytics to achieve significant energy savings for its generators. The company first mined historic data from sensors and records to identify energy waste and usage trends in its generators. This led Goldcorp to identify energy savings of 30% while also lowering its environmental impact.

These themes direct four main roles of digitization in mining going forward. First, digitization in mines −− including data collection, data transfer, and data analysis −− is key to improving productivity. Automation ensures that tasks are completed correctly and consistently every time, eliminating human error caused by the incorrect operation of a machine or a lapse in attention. Second, digitization reduces negative impacts on the environment, such as water contamination and air pollution, by limiting both waste produced and emissions during the mining process. For example, Rio Tinto has partnered with Heliogen, a renewable energy technology company, to deploy AI-powered technology that will use heat from the sun to generate carbon-free energy to power the mine’s processes.

Third, digitization and automation also increase safety for mine workers. Dangerous environments, poor air quality, confined spaces, and lack of structural integrity are just a few examples of safety hazards faced by mineworkers every day. When parts of the mining process are automated, fewer human workers are required which result in less workers’ exposure to the potential hazards found in a mine. For example, BHP provides its experts with HoloLens 2 – a head-mounted computer with a see-through display – so inspections can be done remotely. The mixed-reality wearable allows experts to see what technicians at the site can see, and whenever required, send them helpful documentation and information on the fly, and workers are no longer required to manually inspect. Increased productivity also creates faster and more precise decision-making.

Finally, digital technology enables autonomous decision-making based on real-time information. When data is constantly getting updated with accurate information, it allows for better, faster decisions to be made.

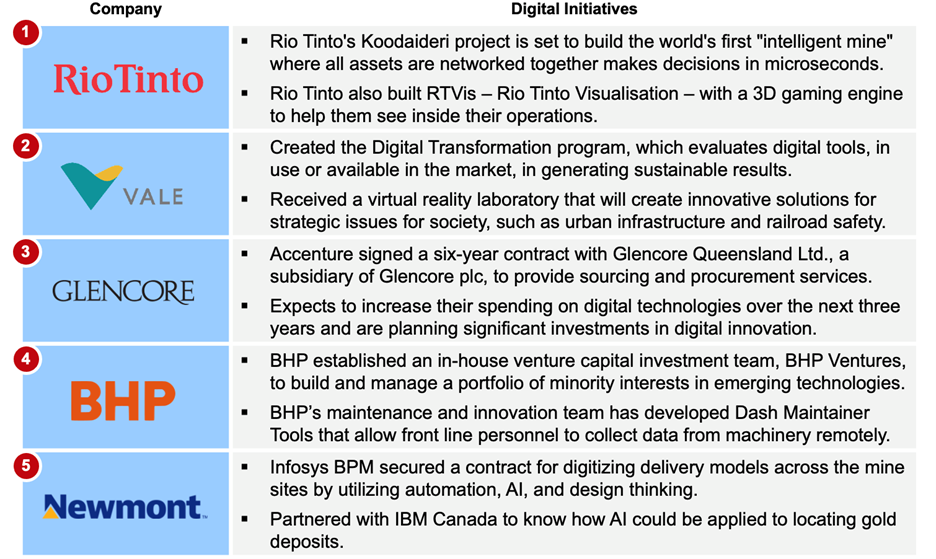

In the past few years, the top mining companies have been going through a digital transformation process (Exhibit 1). Many of these mining companies have been partnering with other companies such as Accenture and IBM. For example, Newmont partnered with IBM Canada to find AI applications in locating gold deposits in Canada’s largest gold mine. Taking all the drilling data and other values that the company had accumulated on the mine, IBM built out a data platform over two years. The resulting AI – called IBM Exploration with Watson – rapidly cut down the time it would take a geologist to identify a potential drill site. In a test, traditional methods of identifying a site took 156 hours. IBM exploration with Watson did it in four and a half. The AI is taking all the data, analyzing correlations with its algorithms to provide recommendations on potential targets.

Other initiatives that mining companies have been taking are creating programs that evaluate emerging or available technologies. As seen in Exhibit 1 for example, Vale created the Digital Transformation program. The idea is to evaluate the potential of digital tools, in use or available in the market, in generating sustainable results. More stable, integrated, and cost-effective operations are some of the expected practical results. Another mining company BHP recently established an in-house venture capital investment team called BHP Ventures to build and manage a portfolio of interests in emerging technology companies, targeting innovation and growth that could increase safety, productivity, and efficiency and will look to provide growth in areas such as exploration.

This and related work in past of ADI’s new multi-client study – “The New Frontier: Critical Minerals & the Energy Transition” – which is focused on a comprehensive assessment and outlook for the critical minerals market through 2030. This 12-week long multi-client study process builds on ADI’s extensive research and deep expertise in metals, minerals, mining, mineral processing, and energy transition. The study will be based on in-depth primary and secondary research and supply and demand modeling and analytics. Please download the multi-client study prospectus – “The New Frontier: Critical Minerals & the Energy Transition”– and contact us to learn more.

Stay tuned for more insights and read our previous blogs on Mining and Metals.

– Sreenidhi Tadigadapa and Swati Singh