ADI Chemical Market Resources sees the ongoing pandemic and the commodity price crash impacting the petrochemical industry in several ways including the following:

- Demand disruptions from the broad economic collapse,

- Feedstock volatility and margin pressures,

- Feedstock supply and product demand imbalances

- Declining sales volumes

- Significant capital spending cuts

- Shift to lower feedstock volatility via crude-to-chemicals

First, the dramatic collapse in economic activity and bleak GDP growth outlook will have a significant impact on petrochemical and polymer sales and hurt margins for chemical producers. Chemical and petrochemical demand and industry growth are highly correlated to economic activity and GDP growth.

Second, feedstock pricing volatility – see our extensive work on the oil and gas “perfect storm” – has grown dramatically impacting and shifting margin dynamics. For example, the oil price collapse has reducing naphtha prices and improved its derivative chemical product margins. Natural gas liquids pricing, on the other hand, has been subjected to extensive volatility given that a lot of it is tied to shale gas and unconventional oil production in North America whose outlook is highly uncertain. Further, with light tight oil production likely to decline, associated gas production will fall potentially increasing natural gas prices and reducing the competitiveness of many North American ethane-linked petrochemical players.

Third, due to the lockdowns in several countries and the corresponding decline in fuel demand, refinery utilization has dropped significantly by 30%- 40% from typical levels. As a lot of these refineries are integrated with the petrochemical projects, we expect feedstock imbalances — shortages for some feedstocks and surpluses for others — for the petrochemical plants. Managing these feedstock imbalances poses a new set of operational and commercial challenges for petrochemical players.

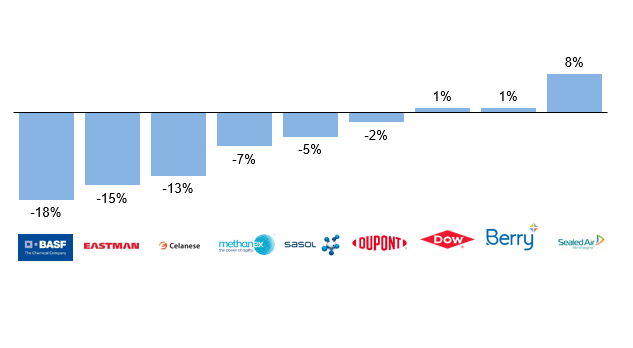

Fourth, these challenges are collectively impacting the financial performance of the chemical and petrochemical industry. For example, most chemical players are reporting big declines in sales volumes. Major players such as BASF, Eastman Chemicals, and Celanese have all reported sales volume declines ranging from ~13% to 18% for the first quarter of 2020 compared to the same time frame last year as shown in Exhibit 1. However, a handful of companies further down in the value chain such as Berry Global and Sealed Air have seen an uptick in sales volumes. Both of these companies have seen significant growth in sales due to the rapidly rising demand for packaging products due to online commerce and consumer packaging.

Exhibit 1: Impact of COVID-19 on sales volumes for major producers (percent change for the first quarter, year-on-year)

Diving deeper into segment-wise impacts in the chemical and petrochemical markets, we see wide variations in impact. For example, chemical producers are reporting sharp declines in polypropylene demand led by the automotive sector. Similarly, the market for PVC and vinyls saw a downward trend due to a fall in housing starts and broader construction activities. On the other hand, demand for polyethylene is still holding up led by consumers, food, and other packaging needs. The widest variation in demand impacts is seen in specialty chemicals and materials where some products such as industrial gases and coatings and adhesives are doing well if serving specific segments, while refining catalysts and lubricants have been impacted.

ADI Chemical Market Resources has developed heat maps for various companies and segments assessing the near- and medium-term impacts of COVID-19. Contact us to learn more >>

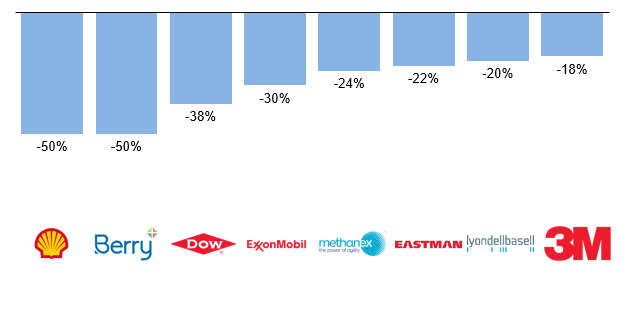

Fifth, due to the impact on sales volumes and profitability, chemical companies have responded by announcing significant cuts in their capital spending plans in 2020. We see a broad range of companies announcing capex cuts as shown in Exhibit 2 including integrated majors such as ExxonMobil and Shell, leading chemical players such as Dow and LyondellBasell, and specialty players such as Eastman and 3M. Even Berry Plastics, which has enjoyed an uptick in sales volumes, also announced capex cuts for this year. Collectively, these capex cuts will limit the ability of these companies to embark on major projects and will instead focus on sustaining capital investments or limited enhancements through revamps and upgrades.

Exhibit 2: Capex cuts announced by major chemical producers as a percentage of initial capex guidance

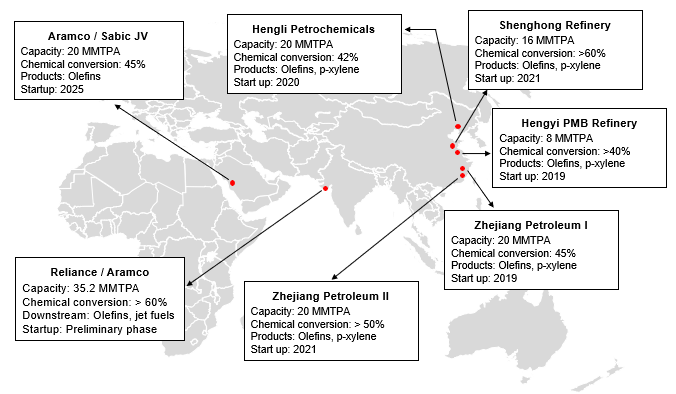

Finally, thinking beyond 2020, we expect feedstock imbalances witnessed due to extensive refinery-petrochemical operational integration to accelerate the shift towards crude-to-chemicals projects. In general, crude-to-chemicals projects do not suffer from these challenges of relying on refineries for feedstock to produce downstream products. There is a renewed interest in this area with several projects already being announced by major companies. Several projects in this area are underway as shown in Exhibit 3.

Exhibit 3: Illustrative list of ongoing crude to chemicals projects

Collectively, the chemical and petrochemical industry is faced with significant challenges that will impact margins in 2020. However, with the economy slowly reopening, the petrochemical sector has already started reporting an uptick in demand sooner than expected in some areas, along with encouraging results from the various strategies that have been deployed to address the challenges from the COVID-19 pandemic. ADI Chemical Market Resources will continue to share insights from our industry research. Please contact us to learn more.

-Utkarsh Gupta, Panuswee Dwivedi, Swati Singh, and Uday Turaga