The greenhouse gas (GHG) footprint of plastics continues to find attention with a recent report published by researchers at Lawrence Berkeley National Lab (LBNL) in April 2024. In the past, this issue was looked at by McKinsey in July 2022 when they estimated life cycle GHG emissions of plastics.

According to the LBNL report, in 2019, the production of virgin plastics emitted ~2.3 billion tons of carbon dioxide equivalent (CO2e) into the atmosphere. This amount surpasses the emissions from both aviation and shipping combined, accounting for a significant 5.3% of total global GHG emissions. If current growth in plastics usage continues, plastics production could account for ~20% to ~30% of total emissions by 2050.

Exhibit 1 presents the GHG emissions breakdown throughout the plastics production process, as detailed by the LBNL study. This process includes extraction of fossil fuels, hydrocarbon (HC) refining and other non-HC chemical production, monomer production, polymerization, and manufacturing of plastic products. The global average GHG emission intensity of plastic products ranges from ~4.5 to 6.5 tons per carbon dioxide equivalent per ton (tCO2e/t) of plastics, in which ~50% of emissions come from fossil fuel extraction, non-HC chemicals production, and HC refining to produce feedstock for plastics.

Exhibit 1. Average GHG emissions associated with plastics production stages (Source: LBNL).

In the LBNL study, the production of different plastic polymers is modeled separately, considering all the steps of the production process, as mentioned above. Material flow analysis is used in the study and the study focuses primarily on the energy consumption and GHG emissions associated with the production of primary plastics polymers, but it does not include the production of additives and catalysts used in smaller amounts in some processes. According to the LBNL study, GHG emissions associated with HDPE and PET plastics production are 4.67 and 6.48 tCO2e/t, respectively. Exhibit 2 represents the breakdown of GHG emissions intensity with HDPE and PET production stages.

Exhibit 2. GHG emissions intensity for HDPE and PET production (Source: LBNL).

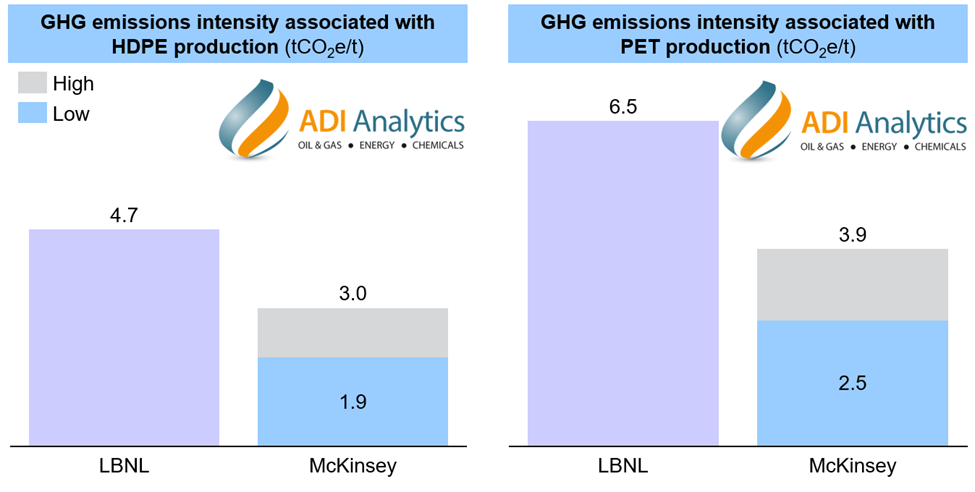

McKinsey has also looked at this issue of GHG emissions associated with plastics and published a life cycle assessment-based report comparing GHG emissions of plastics with alternative materials. The assessment includes both cradle-to-grave emissions as well as product-use impact. The plastics production process in the assessment includes resource extraction, raw-material processing, final product manufacturing, and all transportation steps. According to the McKinsey report, GHG emission intensity associated with HDPE production ranges from ~2 to ~3 tCO2e/t and ~2.5 to ~4 tCO2e/t for PET production. Although McKinsey’s analysis covers cradle-to-grave emissions, their GHG emission intensity values for HDPE and PET plastics production are significantly lower than the estimates from the LBNL study. Exhibit 3 compares the GHG emission intensity results from the LBNL and the McKinsey reports.

Exhibit 3. Comparison of GHG emissions intensity of plastics production from LBNL and McKinsey reports.

The McKinsey report does not break down the GHG emission associated with each specific step involved in the assessment. It also lacks transparency in the assumptions, models used, and data analyzed in the study and hinders reproducibility. In contrast, the LBNL study is far more transparent and has developed a detailed bottom-up model, examining GHG emissions associated with the production of each plastic type, considering all production stages with a comprehensive breakdown of each process from the extraction of fossil fuels to product shaping.

These two studies reflect the challenges associated with life cycle analysis, based on ADI’s experience conducting life cycle analysis of a wide range of plastics, chemicals, and fuels. We see numerous drivers of uncertainty including the following:

- Availability of multiple models and frameworks to estimate life cycle GHG emissions.

- Variations in the manufacturing processes stemming from multiple pathways, feedstocks, efficiencies, locations, and age of plants, and other factors.

- Uncertainty with underlying data and differing approaches to assumptions and target outcome granularity.

Given these drivers of uncertainty, providing complete transparency into methodology will be critical for an effective understanding of life cycle studies on GHG emissions from the production of plastics as well as other materials and fuels.

– Bhautik Gajera and Uday Turaga

Please contact ADI at info@adi-analytics.com if you would like to understand more about GHG emissions and decarbonization in the plastic industry.

ADI Analytics is a prestigious, boutique consulting firm specializing in oil & gas, energy transition, and chemicals since 2009. We bring deep, first-rate expertise in these segments including life cycle analysis of chemicals, plastics, and fuels, where we support Fortune 500, mid-sized and early-stage companies, and investors with consulting services, research reports, and data and analytics, with the goal of delivering actionable outcomes to help our clients achieve tangible results.

We also host the ADI Forum, one of Houston’s distinguished industry conferences, to bring c-suite executives from oil & gas, energy transition, and chemicals together for meaningful dialogue and strategic insights across the value chains.

Subscribe to our newsletter or contact us to learn more.