The industrial sector is capitalizing on AI’s ability to process large amounts of data. Digital twins, internet of things (IoT), generative AI, and machine learning (ML) are all being used by industrials to improve and automate their operations. Specifically, industrials are using AI to enhance product development, optimize production planning, improve supply chain management, and support customer interactions.

With the increased processing power of AI, industrials are expediting product development. Computer-aided design software has been a great tool for engineers working on product optimization, but it has its limitations. Consider a simple project with 10 key components that an engineer would need to design. Each of those components could have upward of 10 design parameters, and there could be as many as 100 unique options for each of those parameters. In the end, this project could have up to 10200 potential design combinations to consider. Only a handful of the most promising designs will ever make it to the testing stage because of the cost and time required to evaluate each one. Such a small sample size means there is a risk that the best performing design will never make it to the testing stage. However, AI and digital twins can be used to model and test exponentially more designs in less time and at a lower cost. The value of AI in product development becomes even more clear when considering that a complex project, like an automobile, would have a nearly limitless number of options to consider.

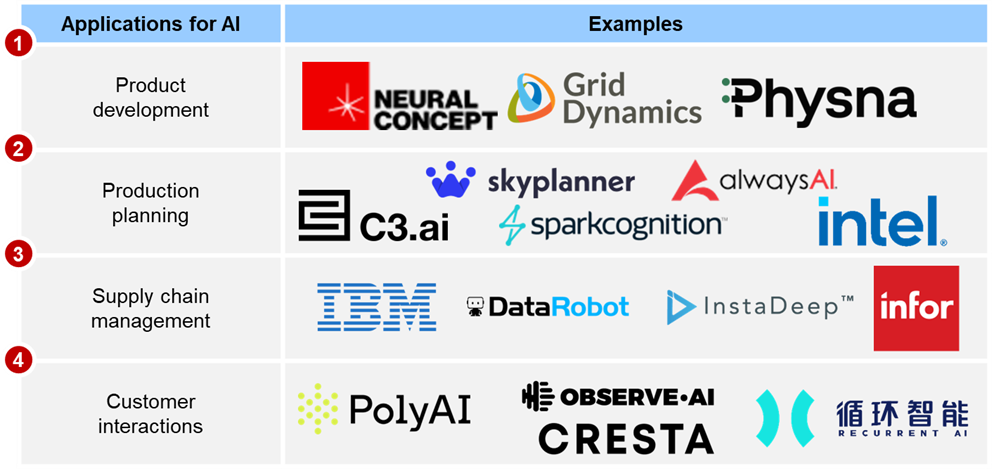

Figure 1. Examples of companies providing AI solutions for industrials

Production planning is another area where industrials are gaining value from AI. Using IoT data, manufacturers can generate digital twins of their operations that accelerate the application of six sigma principles. These digital twins can provide meaningful insights about the process which can be used to optimize production capacity, uptime, quality, and cost. For example, digital twins can be used to analyze equipment and facilitate predictive maintenance, minimizing unexpected downtime and reducing costs. Also, AI-powered scheduling agents are being used in production planning to maximize throughput and minimize changeover costs for complex manufacturing lines.

Industrial manufacturers, much like chemical manufacturers, are using AI to improve their supply chain management. AI solutions provide real-time insights into demand forecasting, inventory management, and logistics which industrials can use to optimize their supply chains. With AI-powered production planning, demand forecasting, and inventory management, industrials can quickly adjust to dynamic supply chains. AI algorithms can also identify inefficiencies in distribution networks then provide solutions to improve delivery performance and balance logistics spending.

AI is also benefitting industrials by supporting customer interactions like sales and customer service. Generative AI can support the sales process by providing targeted and individualized sales messaging. Advanced data analytics with AI can also optimize order scheduling to serve customers quicker and more cost efficiently. On the customer service side, AI can help customers with troubleshooting or even write product manuals. Considering that aftermarket services are a key source of growth in industrials, superior customer service supported by AI will give companies that can implement it well a competitive advantage.

Now that we have covered how AI is growing the global economy in the oil and gas, chemicals, utilities, and industrial sectors, ADI’s short series on how industries are utilizing AI will soon conclude with how the mining sector is making mining safer and more efficient with AI.

-Piercen Hoekstra

ADI Analytics is a prestigious, boutique consulting firm specializing in oil & gas, energy transition, and chemicals since 2009. We bring deep, first-rate expertise in a broad range of markets including oil & gas, chemicals, and utilities, where we support Fortune 500, mid-sized and early-stage companies, and investors with consulting services, research reports, and data and analytics, with the goal of delivering actionable outcomes to help our clients achieve tangible results.

We also host the ADI Forum, one of Houston’s distinguished industry conferences, to bring c-suite executives from oil & gas, energy transition, and chemicals together for meaningful dialogue and strategic insights across the value chains.

Subscribe to our newsletter or contact us to learn more.