As the world moves to a more sustainable future and is advancing ways to reduce greenhouse gases and limit the effects of climate change, direct air capture (DAC) is one process being developed and deployed to remove CO2 from the atmosphere along with other efforts to reduce emissions. This industry is still in its infancy but is continuing to gain momentum. In this blog post, we discuss the industry and some of its recent advancements.

What is DAC?

DAC is a process designed to pull CO2 from the atmosphere via an engineered or mechanical system. Two main systems are in place today that use either liquid solvents (L-DAC) or solid sorbents (S-DAC), with both systems requiring heat to release the CO2 once captured. However, new technologies are being developed that use electrochemical processes that may provide more efficiency. One example is an artificial leaf the University of Illinois Chicago is developing that captures CO2 at a rate one hundred times better than current systems.

Technology readiness

When measured by technology readiness level (TRL), carbon capture systems are fairly mature. However, the TRL can vary by type of carbon capture. A recent report by the U.S. Government Accountability Office indicates a TRL of 7 (out of 9) for direct air capture while post-combustion capture has a TRL of 9. A TRL of 7 is considered mature as the technology is past the research and development phases, has been validated by a pilot study, and is in the full-scale development phase.

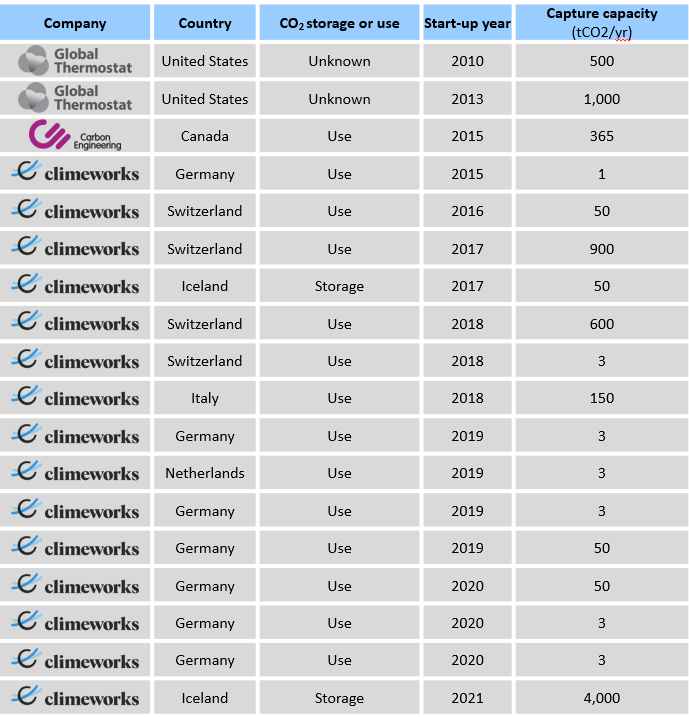

There are 18 DAC facilities globally (Exhibit 1), located in Canada, Europe, and the U.S., that collectively can capture just under 8,000 metric tons of CO2 (tCO2) per year. About half of that is permanently stored while the other half is used for various purposes. For perspective, global energy-related CO2 emissions totaled 36.3 billion tonnes in 2021, while traditional carbon capture facilities in operation have a total capacity of 36.3 million tCO2 (MtCO2) per year with another 100+ MtCO2 of capacity being developed. The largest of the DAC facilities is the Orca plant in Iceland, built by Climeworks in 2021. Orca is designed to remove 4,000 tonnes of CO2 annually by dissolving it in water and injecting it underground where chemical reactions will turn it into rock. Additional projects are in development and will be discussed subsequently.

Costs

The biggest challenge for DAC technology is the cost of both the equipment and CO2 removal costs. DAC is energy intensive and the most expensive carbon capturing process available, as shown in Exhibit 2. Several factors influence this range in prices: technology used, size of the facility, source of energy, and how the captured carbon will be used (i.e., geologic sequestration or immediate use). These costs are in addition to estimated capital expenditures, estimated at $780 to $1,100 million for a 1 Mt tCO2 per year facility, as well as transportation and storage costs. For perspective, reforestation has costs as low as $10 per ton of CO2 captured. One of the biggest reasons costs are so high for DAC is that there are relatively few DAC companies/projects and executing more projects and capacity growth will ultimately lead to reduced costs.

Resource Implications

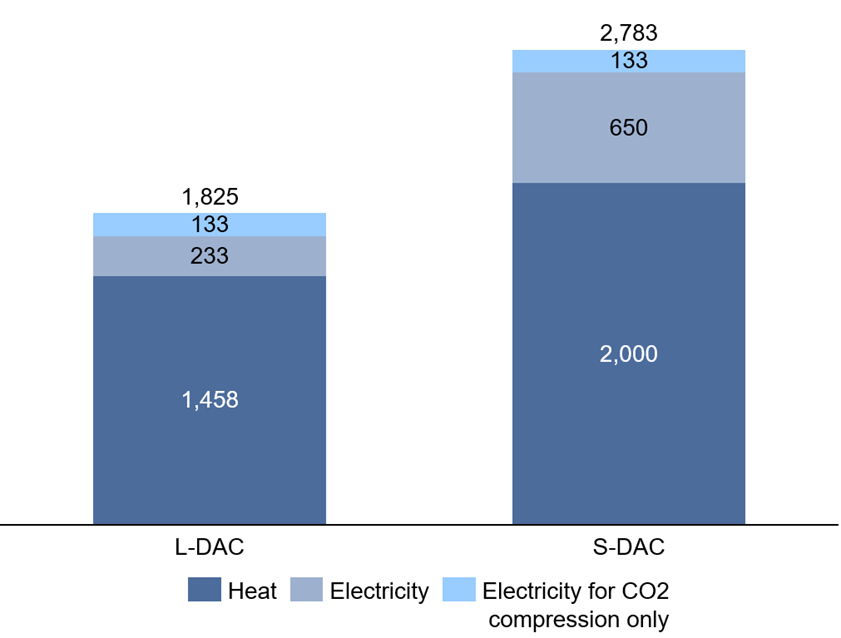

Both technologies for DAC in use today (L-DAC and S-DAC) have different temperature requirements. L-DAC requires high heat (900°C) whereas S-DAC requires low heat (80°-120°C), allowing S-DAC to use waste heat from industrial process and renewable energy. Both processes require significant energy as shown in Exhibit 3 and scaling up these systems as they exist today would use significant amounts of electricity. Energy sources for DAC need to have zero or near zero carbon emissions to maximize net capture efficiency.

Land use is often cited as a concern for many carbon solutions. For DAC, the footprint is minimal for the facility itself, meaning that the impacts on land are low. Total land area needed will depend on the DAC technology utilized and the source of energy powering it, as shown in Exhibit 4. Surface are needed can range from 0.4 to 66 km2 for a 1 MtCO2 per year facility. On the other hand, to capture a similar amount of carbon from a forest would require 862 km2.

Water use for DAC also depends on the technology utilized and may be significant. An L-DAC system can use 1 to 7 tonnes of water to capture 1 tonne of CO2. Water loss is mainly due to evaporation, so the temperature and humidity at the plant are key factors. On the other hand, S-DAC systems can use 1.6 tonnes of water per tonne of CO2, but some systems, such as Climework’s system, can produce water from CO2 capture due to the indirect heating system used.

Summary

Direct air capture is becoming a larger part of the net-zero discussion. New DAC technologies are starting to emerge, but much remains to be done to reduce costs and improve efficiencies. Additionally, many of the DAC facilities in place today capture carbon to use in a commercial process. As DAC advances, the permanent sequestration of the captured carbon is necessary to achieve emissions goals.

This is part of our Going Blue blog series on carbon capture. ADI Analytics closely monitors energy policies and the energy transition. Contact us to learn more about our research and how we can help.

– Dustin Stolz