Rapid growth in the adoption of alternatives to fossil fuels is driven by the lower lifecycle greenhouse gas (GHG) emissions of alternative fuels. Hydrothermal liquefaction (HTL), pyrolysis, photocatalysis, and gasification are some of the technologies to produce biofuels at various stages of technology advancement and commercialization today. HTL is one of the more promising technologies in terms of prospects for commercial use.

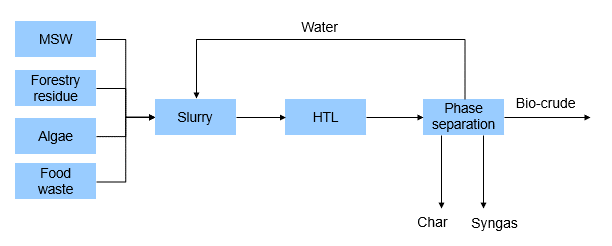

HTL involves hydrolyzing biomass (or end-of-life plastics) at temperatures between 350 and 700 °F and pressures ranging from 1,400 to 3,600 psi. Biomasses can be wood, forestry residues, algae, food waste, municipal solid waste (MSW), or sewage sludge. End-of-life plastics can also be used as feedstock. The feedstock is made into a slurry that passes through the HTL reactor operating in conditions close to the water’s supercritical point. The stream out of the HTL reactor goes through phase separation, and all the products go to different streams. The main product from the HTL reactor is a renewable version of crude oil. Exhibit 1 shows a block flow diagram of converting biomass to bio-crude. The bio-crude can be upgraded into renewable fuels, such as green diesel or sustainable aviation fuel (SAF).

Exhibit 1: HTL Block Flow Diagram for biomass to bio-crude.

Some of the advantages of HTL, compared to other biofuel technologies, are that it generates higher energy density products, requires a shorter reaction period, and can be applied to a broader range of materials. Additionally, the resulting liquid product has lower oxygen content than other methods such as pyrolysis, making it more stable to be used as a fuel.

Growing commercial interest

Several companies are working towards scaling up their HTL technologies from pilot and demo plants to commercial scale. For instance, Licella’s patented Catalytic Hydrothermal Reactor (Cat-HTR) process uses lignocellulosic biomass or end-of-life plastics as feedstock. Licella and Canadian integrated forest products company, Canfor, have partnered to use biomass as feedstock to produce 50,000 barrels per year of bio-crude in Prince George, British Columbia. Licella has also partnered with Neste, the world’s largest renewable diesel producer, to explore the use of mixed plastic waste as feedstock. Other alliances of Licella, through its joint venture (JV) Mura Technology, include KBR and Shell Catalysts. The Mura JV is now the exclusive licensor for Cat-HTR as a plastics recycling technology outside Australia and New Zealand. Another technology developer, Steeper Energy, has a pilot plant in Norway producing 25 barrels per day of renewable crude oil which can be upgraded to renewable diesel. In December of 2021, Steeper Energy agreed with Maersk to supply renewable fuel for their maritime operations. Other projects, such as Nextgen Roadfuels, coordinated by Aalborg University in Denmark, are aimed at optimizing the yields of HTL for large-scale operations.

Commercialization challenges

Currently, HTL is in development to transition from batch reactors to continuous systems. Operating in continuous systems maximizes the bio-crude output. Another challenge in HTL is the operating temperature. The yield increases with temperature up to water’s critical point, which results in the repolymerization of intermediate products, thus decreasing the process performance. While the percentage of oxygen decreases and carbon increases at higher temperatures, the overall output decreases. The ideal temperature to maximize output results in lower quality bio-crude, while the highest quality product requires sacrificing total output.

HTL is a promising technology capable of delivering alternative fuels with minimal environmental impact compared to their fossil counterparts. Partnerships between existing players and start-ups are essential to scale up alternative fuels supply and compete with other production pathways. Exhibit 2 shows the cooperation between catalyst/technology companies, EPCs, and start-ups. More partnerships will increase the awareness of HTL and speed up its adoption.

Exhibit 2: Active HTL players in the energy supply chain.

ADI Analytics is closely following the renewable fuels market and its various production pathways. Subscribe to our newsletter to stay updated with the latest advances in alternative fuels, or contact us to learn more.

-Manuel Diaz