The global shipping industry is one of the hard-to-abate industries when it comes to decarbonization. While it constitutes a small share of global CO2 emissions today, it may see astronomical amount of growth if left unchecked. Global shipping industry demand is expected to see a 275% increase by 2050 compared to 2020 levels. To address concerns of growing carbon emissions, the International Maritime Organization (IMO) set a goal to reduce the shipping industry’s carbon emissions by 40% by 2030 and 70% by 2050, compared to 2008 levels. In addition, IMO 2020 also has driven a shift in low-sulfur fuel alternatives for marine industry. Fuel switching is considered as the most feasible option to decarbonize the industry today considering challenges with limited availability of space for carbon capture.

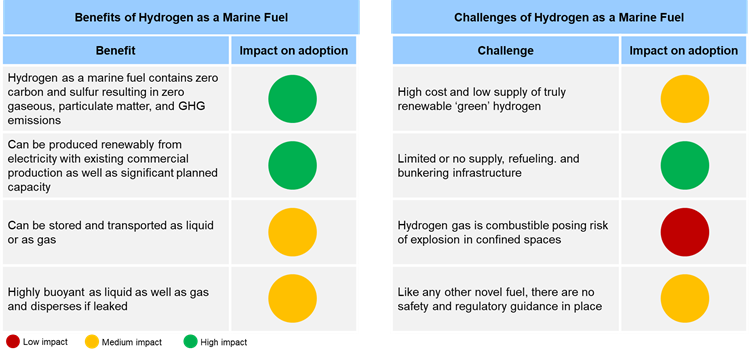

ADI has researched various options for the marine industry including buffer installations, switching to low, very low, or ultra-low sulfur fuel oil, and alternative fuels such as LNG, methanol, ammonia, and hydrogen. ADI recently presented its findings on potential of hydrogen as a marine fuel at the 2022 Maritime Air Pollution & Fuel Technologies Conference in Houston. While there are several benefits of potentially using hydrogen as a marine fuel, there are also some key challenges that cannot be ignored. Exhibit 1 below summarizes the key benefits and challenges of hydrogen as a marine fuel and describes the impact of each on adoption.

Exhibit 1. Benefits and challenges of hydrogen as a marine fuel

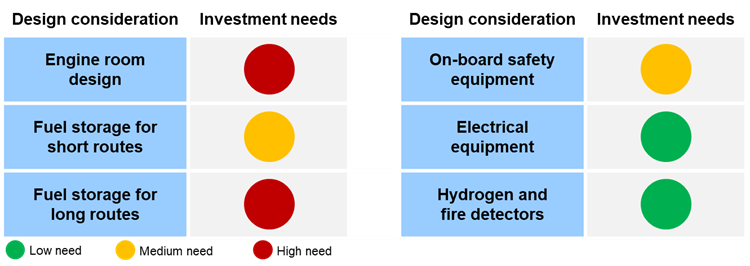

In addition to the above benefits and challenges, hydrogen cannot be used as a drop-in fuel with conventional marine fuel. Several design aspects including engine room design, adequate fuel storage for short and long routes, on-board safety equipment to treat the boil-off gas on board, electrical equipment to minimize fire risk in and around storage and hazardous zones on the ship, and hydrogen and fire detectors at appropriate locations on the ship will have to be considered. Each of these will need varying levels of investment as summarized in the exhibit below.

Exhibit 2. Investment needs for various design considerations to use hydrogen as marine fuel

As seen in the exhibit above, engine room design and fuel storage for long routes will need a lot more investment than fuel storage for short routes and on-board safety equipment as some of it can be addressed via retrofit. In case of appropriate electrical equipment and hydrogen and fire detectors, they are considered as low investment needs as most of the regulations for hazardous area safety will remain fairly similar to any other fuel system.

Talking about infrastructure and shipping needs for wider adoption of hydrogen as marine fuel, hydrogen fueling stations at ports will need to be installed which will require significant support from the government agencies and policies to reduce the cost of hydrogen production, distribution, and acquisition. Liquid hydrogen is expected to be bunkered similarly to LNG while gaseous hydrogen may be bunkered with frequent loading or unloading in between ships and terminals as approved to relevant authorities including road transport regulators and shipping regulators. Bunkering hydrogen is expected to be more cost-intensive than LNG due to increased cryogenic storage requirements and advanced components for safety. Shipping hydrogen will be imperative and several hydrogen shipping options have been explored by ADI in the past. ADI tracks regulatory landscape and fuel alternatives in the marine industry as well as closely follows the hydrogen market. Contact us to learn more. Download the prospectus to our multi-client study: Fueling Strategies to Decarbonize Shipping here.

By Panuswee Dwivedi