Several countries have laid out hydrogen strategies in the journey to energy transition. For example, South Korea is aiming to quadruple current annual demand for hydrogen to 2 million tons per year (MMTPA) by 2030 and grow to 5 MMTPA by 2050. Similarly, Japan is aiming to consume 3 MMTPA by 2030, rising to 20 MMTPA by 2050. However, both countries will struggle to meet growing demand for green hydrogen domestically. Neither is blessed with plentiful cheap renewable resources. They are intending to expand their offshore wind capacity production, but that poses technical and cost barriers. One possible route is to import hydrogen via ship and deliver it for domestic needs, but the costs and technology limitations associated with shipping hydrogen need to be addressed.

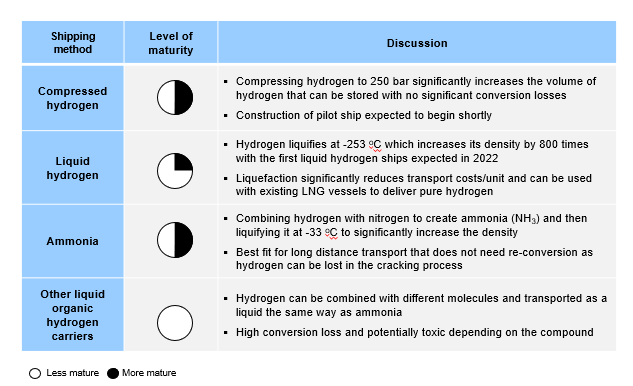

Merchant shipping companies are beginning to develop a new generation of vessels that can deliver hydrogen that betting plants worldwide will convert to the fuel and propel the transition to a lower-carbon economy. To capitalize on the export opportunity requires a cost-effective method of transporting green hydrogen via long distance. However, hydrogen has a low volumetric energy density, so transporting it efficiently requires it to be compressed, liquified or combined with other elements. Exhibit 1 shows four potential solutions and their maturity levels and corresponding challenges. Transporting hydrogen as ammonia seems to be the most cost-effective solution over long distances whereas liquefaction or compressed hydrogen pathways are more preferred for shorter distances (~2,000 nautical miles).

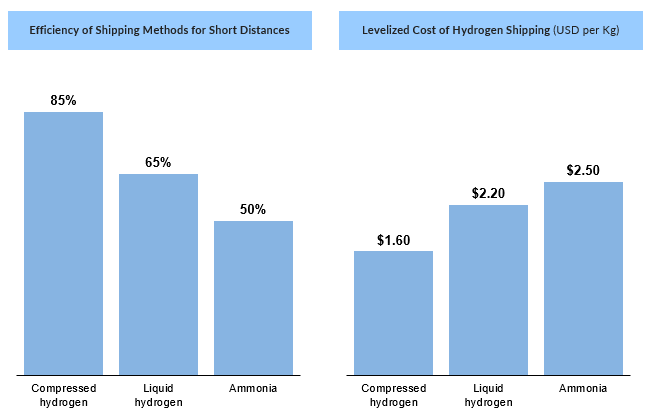

Exhibit 2 shows the efficiency levels of delivered hydrogen via all the pathways as a function of distance. Compressed hydrogen can transport 85% of the supplied hydrogen for shorter distances as it has neither the losses associated with conversion to ammonia nor the energy penalty of liquefaction. On a levelized cost of hydrogen basis, the cost associated with transporting hydrogen in the compressed form for 2,000 nautical miles is ~$1.60 per kg whereas transporting hydrogen with ammonia as liquid carries can cost as much as ~$2.50 per kg.

Most of these technologies are currently in pilot stages and the earliest commercial deployment is in 2022. Japan’s Kawasaki Heavy Industries has already built the world’s first ship to transport hydrogen named Suiso Frontier. The prototype vessel is undergoing sea trials, with a demonstration maiden voyage of ~9,000 km from Australia to Japan expected in 2022.

Australia, with its combination of plentiful solar and wind resources, is one of the cheapest sources of renewable energy. Exhibit 3 shows the total cost of importing hydrogen via ammonia from Australia to mainland South Korea or Japan. We see a differential of 35% between import costs and domestic production of green hydrogen. However, Hydrogen Council expects a significant export opportunity for Australia with aggressive hydrogen demand targets setup by South Korea and Japan and limited potential to meet this demand domestically.

The role of shipping will be important in unlocking the potential to convert industries such as steel and cement to hydrogen. However, the cost of a vessel transporting hydrogen will mainly be driven by the cost of the storage system with higher costs associated with storing liquid hydrogen.

Our team at ADI Analytics has supported a wide range of clients focused on energy including oil and gas, power and utilities, renewables, and energy transition including hydrogen. Please reach out to learn more about how we can help.

-Thomas Dennis and Utkarsh Gupta