The automotive industry in China has been the largest in the world measured by automobile unit production since 2008. After more than 30 years of rapid and continuous growth, auto manufacturers are staring at a new reality in which passenger car sales are on the decline and market fundamentals are shifting from the sale of internal combustion engine cars to the pioneering of next-generation mobility experiences and technologies.

The recent initiatives by governments worldwide to push for lighter, more efficient, and environmentally-friendly vehicles have gathered significant momentum in China. The country’s automakers are now focusing on replacing smaller vehicles with electric vehicles (EVs). Part of the answer is leveraging new technology and using different materials in the body structure of electric vehicles. They have been limiting their use of high-strength steel, reserving it for parts like bumpers and reinforcing beams. Original equipment manufacturers – or OEMs – use lighter-weight materials like aluminum, steel alloys, plastics, and carbon fiber throughout the vehicle.

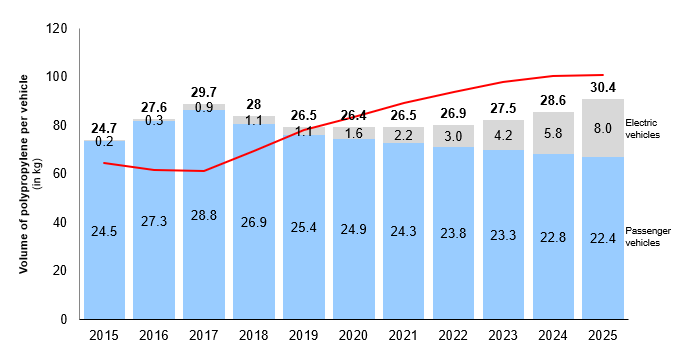

The car production in China has seen a decline in recent years but the number of EVs produced has increased dramatically. In 2020, ~24.9 million passenger vehicles were sold out of which only 1.6 million were electric vehicles as compared to a total of 29.7 million vehicles sold in 2017. Going forward, we expect the growth in car sales to be slow but steady. In the mid- to long-term, we believe the demand profile for vehicle sales in China is encouraging, and that the country will remain the world’s largest market for cars. Car sales are expected to reach ~30.4 million out of which ~24% will comprise electric vehicles as shown in Exhibit 1.

Exhibit 1: Number of cars produced in China, in millions, and volume of polypropylene used per vehicles, in kg

The graph also shows the increasing demand for polypropylene and other plastics in automotive industry in China over the coming years. More and more automakers are replacing metals with plastic-based products to increase durability, stiffness, and reducing the overall weight of the car. The average volume of polypropylene per vehicle was ~63 kg in 2017 which is expected to reach ~100 kg by 2025. The increase in use of plastics and reduction in metal-based parts is expected to reduce the overall weight of cars in coming years.

ADI has done a lot of work covering these trends. We have been following the current global trends in the automobile and plastics industry. Specifically, we have looked carefully at the use of plastics in automobiles. One example is polypropylene where ADI has released a new multi-client study. Please contact us to learn more.

-Utkarsh Gupta and Uday Turaga