Pad drilling, sometimes called multi-well pad drilling, is a drilling practice that allows multiple wellbores to be drilled from a single pad. With a low-priced environment, oil and gas operators are trying to squeeze maximum value for their investments with bigger well pads and longer laterals. Multi-well pad drilling allows for maximum reservoir penetration with minimal surface disturbance, which is important in areas that are environmentally sensitive, have little infrastructure, or in mountainous areas.

Earlier pad drilling involved as few as two to three wells, but the focus has now moved to drilling larger number of wells per pad. These days, operators are pushing the boundaries in shale field development and optimizing costs by using super pads to drill as many as 24 to 40 wells from the same pad location.

Join us at the 2020 ADI Forum on January 15 in Houston where Chris Chandler, Executive Vice President and Chief Operating Officer, Plains All America will be our Keynote Speaker. www.adi-forum.com

In the Permian Basin, Encana has built a “mega pad” that is slated to hold 64 wells. The technique is designed to tap into multiple layers of petroleum-soaked rock all at once, rather than the one-or-two-well, one-layer-at-a-time approach of the past. QEP is utilizing “tank-style” development, in which it simultaneously develops multiple subsurface targets by drilling and completing all wells in each “tank” before any individual well is turned to production.

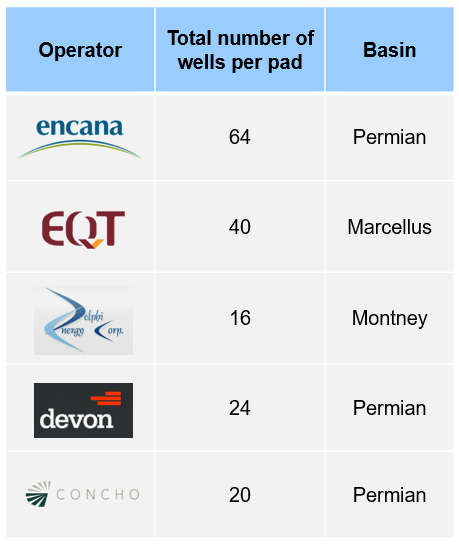

Devon Energy has more than 10 multi-zone projects scheduled, including the 11-well Boomslang pad in the Permian and the 24-well Showboat project in Oklahoma. Concho Resources debuted its Brass-Monkey operation in the Permian and Range Resources in Marcellus developed well pads big enough to accommodate 20 wells. An illustrative list of operators focused on multi-pad drilling is shown in Exhibit 1.

Exhibit 1: Illustrative list of operators drilling multiple wells per well pad

Drilling operators are achieving efficiency gains by drilling multiple wells through a single pad. Operators in the Eagle Ford shale formation averaged about 19 days to drill a horizontal well in 2018, down from an average of 23 days few years ago. In the North Dakota section of the Bakken formation, the increase in drilling rigs in the area has begun to slow, but production levels continue to reach record highs, primarily due to multi-pad drilling techniques. Multi-Pad drilling has many advantages, but it’s not without challenges. While it helps consolidate the facilities, and to reduce rig moves and surface footprints, it also presents complex challenges in terms of slot optimization, shallow-depth anti-collision, and operational and scheduling activities.

This and other innovations collectively continue to bend the cost curve for unconventional oil and gas resource development. ADI has been modeling and analyzing shale gas and light tight oil drilling and completion costs and forecasting well and resource productivity since 2012. Please reach out to us to learn more.

-Utkarsh Gupta and Uday Turaga