Flaring is the controlled burning of natural gas that cannot be processed or sold. When natural gas is vented, the pollutant that enters the atmosphere is methane. Although flaring is less environmentally damaging, it is still a waste of valuable energy resources. Because natural gas is valuable, companies would rather capture than flare it.

Due to constraints in pipeline capacity and storage facilities, gas flaring in the Bakken and Permian have increased rapidly. Constraints in the Permian are likely to be debottlenecked soon with the addition of new infrastructure while the Bakken has a daunting task ahead. Tighter gas flaring regulations from the North Dakota Industrial Commission (NDIC) and a lack of new gas processing infrastructure pose risks for Bakken operators and oil production growth going forward. However, there is an opportunity for the Bakken to produce more natural gas and NGLs by developing more infrastructure and implementing new technologies to capture excessive gases.

The NDIC has announced new gas capture goals at 85% of produced natural gas volume through October 31, 2018, 88% through November 2020, and 91% thereafter. These regulations force the operators to limit oil production to meet flare targets. The new rules limit flaring to one year after first production from a well, after which time producers must either connect the well to a gas gathering pipeline, cap it or link it to an electrical generator or a compression or liquefaction system.

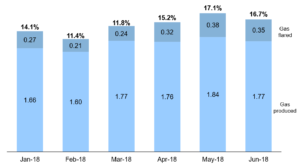

Exhibit 1 shows the amount of gas flared relative to the total volume of gas produced in Bakken over the past six months. Gas flaring for the past months has exceeded the present regulatory flaring limit of 15% set by the NDIC.

Exhibit 1. Gas flared relative to total natural gas production (billion cubic feet per day).

Despite looming constraints, production will continually increase due to rising oil prices and rig counts. This provides an opportunity for more pipeline infrastructure and gas processing plants. Majority of the gas produced is being transported by rail because of pipeline limitations. Kinder Morgan is building a new pipeline investing $30 million project that would connect the existing Kinder Morgan Brogger compressor station in Williams County to the company’s natural gas gathering system in McKenzie County. The project is estimated to capture ~130 million cubic feet per day of now flared natural gas. Developing NGL infrastructure is part of the solution to reduce gas flaring. Oneok has also proposed the 900-mile Elk Creek Pipeline to transport NGL from the Bakken to Kansas.

ADI sees a need for more gas gathering infrastructure at in-fill drilling sites, assessments of using associated gas upstream of gas processing plants, and economic separation and production of natural gas liquids at small scales at well sites. However, there are significant challenges in adopting them commercially. New standards set by NDIC will be the main driver for these new technologies and processes.

– Utkarsh Gupta and Uday Turaga